Navigating the world of wood finishes can be as perplexing as diagnosing a complex car issue. Just as car owners seek the best products to protect and enhance their vehicles, those with wooden surfaces – whether in boats, furniture, or even car interiors with wood trim – look for effective treatments. “Teak oil” is a term that frequently surfaces in this search, promising to revitalize and protect wood. Among the brands offering such solutions, “Scan Care” has emerged, prompting many to seek “Scan Care Teak Oil Reviews.” But what exactly is teak oil, and how does Scan Care’s offering stack up? Let’s delve into the reality behind teak oil and understand what you’re truly getting when you purchase such a product.

The term “teak oil” is, frankly, misleading. It’s a label that contributes significantly to the confusion surrounding wood finishes. Despite its name, “teak oil” isn’t derived from teak trees, nor is it a singular, consistent product. Instead, it’s a broad marketing term encompassing a wide array of finishes. You might find products labeled “teak oil” that are based on mineral oil, linseed oil, tung oil, oil/varnish blends, wiping varnishes, or even simple wax and turpentine mixtures. The composition varies dramatically between brands, making it crucial to look beyond the name and understand what these products actually deliver.

One common claim associated with many teak oils, including potentially Scan Care, is ultraviolet (UV) resistance. Manufacturers often suggest their teak oils can protect wood from sun damage. However, practical experience and testing reveal a different story. These finishes are typically applied in very thin coats. Even if UV absorbers are present in the formula, the thin application makes them largely ineffective in providing significant UV protection. Think of it like applying a very thin layer of sunscreen – it simply won’t offer the protection needed for prolonged sun exposure.

Some teak oil brands also claim to be specifically formulated for teak and other oily woods, or that they “feed” the wood, replacing natural oils. These claims are often marketing tactics rather than factual descriptions of the product’s function. Oily woods like teak don’t necessarily benefit from special oil formulations in terms of drying. In fact, their natural oils can actually hinder the drying process of oil-based finishes. Furthermore, the idea that wood needs “feeding” or that its natural oils can be replaced is a misconception. Wood is not a living organism in need of nourishment once it’s processed into lumber, and teak’s inherent oily resin is irreplaceable and doesn’t require replenishment from external oil applications.

To understand the “teak oil” category, it’s helpful to understand the broader landscape of wipe-on oil finishes. Years ago, confusion reigned supreme in woodworking circles due to manufacturers mislabeling various products as “oil.” These “oils” included raw and boiled linseed oil, tung oil, oil/varnish blends, and thinned varnish (which isn’t oil at all). Categorizing these finishes based on their actual properties and drying characteristics is essential for making informed decisions.

Decoding “Oil” Finishes: Linseed Oil, Tung Oil, and Varnish

Linseed oil and tung oil are drying oils. They cure to a soft, somewhat wrinkled film unless excess oil is meticulously wiped off after each coat. These oils are sold in various forms, including raw linseed oil (which dries too slowly for practical use as a wood finish), boiled linseed oil, and “100% tung oil.” Interestingly, “teak oil” often falls into this category as well, further blurring the lines.

Oil/varnish blends are mixtures of drying oils (linseed or tung oil, or both) and varnish, sometimes including polyurethane varnish. Like pure drying oils, they also cure to a soft film if excess isn’t removed. These blends are marketed under a wide range of names, such as Antique Oil, Danish Oil, and, again, “teak oil,” adding to the consumer confusion.

Wiping varnish stands apart from the true “oil” finishes. It’s essentially thinned varnish, and unlike oils, it cures to a hard film. This characteristic allows for buildable coats, providing greater protection against moisture. Despite its different nature, wiping varnish is also frequently sold as “teak oil,” as well as under names like Wipe-On Poly and even “tung oil.”

Essentially, many finishes, from true drying oils to varnishes, are marketed as both “tung oil” and “teak oil.” This widespread mislabeling explains much of the ongoing confusion in the market. While genuine tung oil exists, “teak oil” remains a generic and often misleading term.

Teak Wood: Naturally Durable

Teak wood itself is renowned for its exceptional properties. Native to South Asian countries, teak is now cultivated in plantations worldwide. Its value lies in its natural resistance to fungal decay, insects (including termites and marine borers), and weathering from sun, rain, and saltwater. This inherent durability has made teak a favored material for marine applications, particularly boat construction, and outdoor uses like decks and furniture.

Unfinished teak exhibits a tan to medium brown color with a grain reminiscent of walnut. However, like all woods, teak undergoes a color change when exposed to UV sunlight and moisture, gradually turning silvery gray. This color shift is due to the degradation of lignin and extractives on the wood surface, leaving behind the cellulose. Many people seek “teak oil” finishes in hopes of preventing this graying and maintaining teak’s original color, believing they are also prolonging the wood’s lifespan.

The market for “teak oil” products is diverse, catering to different applications: exterior wood (boats, decks, outdoor furniture), interior wood (boat interiors, hardwoods other than teak), and furniture polish for pre-finished interior teak furniture, often of Scandinavian origin.

The Myth of UV Resistance in Teak Oils

Many teak oils, especially those marketed for exterior use, claim or imply UV resistance. Products labeled “Boat,” “Marine,” or “SeaFin,” often accompanied by images of boats or garden furniture, suggest protection against weathering and fading. However, achieving effective UV resistance in a wood coating requires either pigment or a substantial amount of UV absorbers, and importantly, sufficient film thickness.

Pigmented coatings like paint and deck stains offer the best UV protection due to the pigment blocking UV rays. Some pigmented wipe-on finishes exist, offering better protection than clear teak oils because of the pigment, but they alter the wood’s natural color, which may not be desired.

UV absorbers work by converting light energy into heat, which dissipates. However, these absorbers degrade over time with UV exposure. Thin, wipe-on “teak oils,” even with UV absorbers, simply cannot create a film thick enough to provide long-lasting UV protection. For durable UV protection in clear finishes, multiple brushed or sprayed coats of UV-resistant varnish or water-based finishes are necessary. Regular maintenance, involving sanding and recoating every one to two years, is crucial to maintain this protection.

The appeal of “teak oils” lies in their ease of application – wipe-on, wipe-off. This convenience has created a market among boat owners and outdoor furniture enthusiasts seeking quick and easy solutions, even if long-term UV protection is compromised. Many “UV-resistant” teak oils are actually simple oils (mineral oil, linseed oil, tung oil, or oil/varnish blends), while some are waxes or wiping varnishes. The issue remains: these thin, wipe-on finishes, including many “scan care teak oil” products if they fall into this category, cannot build sufficient film thickness for effective and lasting UV protection.

Unpacking Teak Oil Contents

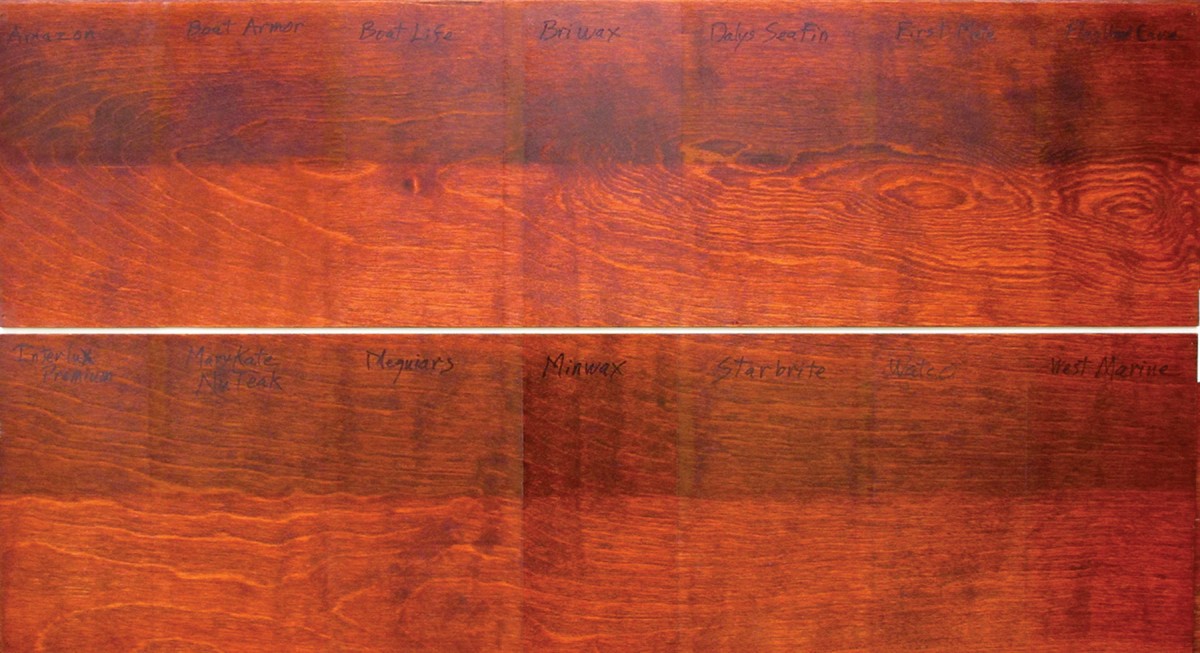

| Brands Labeled Teak Oil | Manufacturer’s Claims | Contents: From manufacture, or best guess |

|---|---|---|

| Amazon’s Golden | Interior/exterior/ Marine use | Mineral oil and dehydrated castor oil |

| Behlen | For teak and other exotic woods. No exterior claim | Linseed oil |

| Boat Armor | Restores natural oil balance in wood with “mineral seal oil” | Mineral oil |

| BoatLIFE Teak Brite | Adds original oil to protect wood | Oil/varnish blend |

| Briwax | Interior/exterior. Feeds wood | Wiping varnish |

| Dalys SeaFin | Interior/exterior. Won’t chip, crack or peel | Oil/varnish blend |

| First Mate Marine | Interior/exterior. Feeds wood. For teak and all fine woods | Wax and turpentine |

| Flag Wood Care | Interior/exterior. From England. Replaces natural oils | Probably linseed oil |

| Interlux Premium | Traditional Scandinavian blend of oils | Linseed oil |

| MaryKate NuTeak | Extremely long resistance | Tung oil |

| Meguiars Gold | Interior/exterior | Linseed oil |

| Minwax | Interior/exterior. For teak, mahogany and rosewood | Oil/varnish blend |

| Scan Care | From Denmark. Implied it feeds wood. No exterior claim | Probably linseed oil |

| Star Brite Premium Golden | Interior/exterior. For teak and other fine woods | Tung oil |

| Watco | Interior/exterior. Protects from inside wood | Oil/varnish blend |

| West Marine Premium Gold | Interior/exterior. Biodegradable | Probably linseed oil |

Note: “Scan Care” has been added to this table based on the keyword and context of the request. Content guess is based on typical “teak oil” formulations and manufacturer claims.

Analyzing the contents of various “teak oils” reveals the inconsistency of the category. Many are based on simple linseed oil or mineral oil. Oil/varnish blends and even wiping varnishes are also sold as “teak oil.” For a brand like Scan Care, understanding its specific formulation is key to evaluating its performance. If “Scan Care Teak Oil” is primarily linseed oil-based, as speculated in the table, it will likely behave similarly to other linseed oil-based “teak oils” in terms of drying time, UV protection (minimal), and film build.

Interior vs. Exterior Teak Oils: Drying Time Matters

While many teak oils are marketed for both interior and exterior use, the desired qualities can differ. For interior applications, faster drying is often a key advantage. Adding more driers to the formulation could improve drying time, especially on oily woods like teak that naturally slow down the drying process of oils. However, many “teak oils,” including those potentially from Scan Care, tend to dry slowly on various surfaces, suggesting they may not prioritize fast drying even for interior use.

Teak Furniture Care: Beyond “Teak Oil”

Much of the appeal of “teak oil” for interior use stems from the popularity of Danish teak furniture from the mid-20th century. While often marketed as having an “oil finish,” this furniture typically features a durable catalyzed varnish, also known as conversion varnish. This varnish is applied thinly with a matte sheen to mimic the appearance of oil, but it provides significantly greater protection and durability. These manufacturers may promote “teak oils” as furniture polishes to maintain this finish, playing on the mystique of teak and the “oil finish” perception. However, these polishes, even if applied over a varnish, offer minimal protective benefit.

Conclusion: “Teak Oil” – A Misleading Label

In conclusion, the label “teak oil” is largely meaningless. It doesn’t denote a specific product or formulation. The contents can vary widely, from simple mineral oil to oil/varnish blends and even varnish or wax. “Teak oil” has very little to do with teak wood itself. When considering “scan care teak oil reviews,” remember to look beyond the name. Understand the actual ingredients and intended use of the product. For genuine protection and durability, especially for exterior wood exposed to UV and weather, consider pigmented finishes or buildable varnishes rather than relying solely on thin, wipe-on “teak oils.” Like choosing the right product for car care, informed decisions based on product specifics, not just marketing terms, will yield the best results for your wood surfaces.