The P0507 code might seem like a minor issue at first glance, especially when compared to more alarming error messages like “engine malfunction.” However, this seemingly unassuming code can indicate a significant problem within your vehicle’s idle control system, potentially affecting fuel efficiency, engine performance, and even long-term engine health.

In this comprehensive guide, we will delve into the intricacies of the P0507 code. As expert auto repair content creators at carcodepro.com, our goal is to provide you with an in-depth understanding of this code, covering everything from its definition and symptoms to diagnostic procedures and effective solutions.

Close-up of a car dashboard with the check engine light illuminated.

Close-up of a car dashboard with the check engine light illuminated.

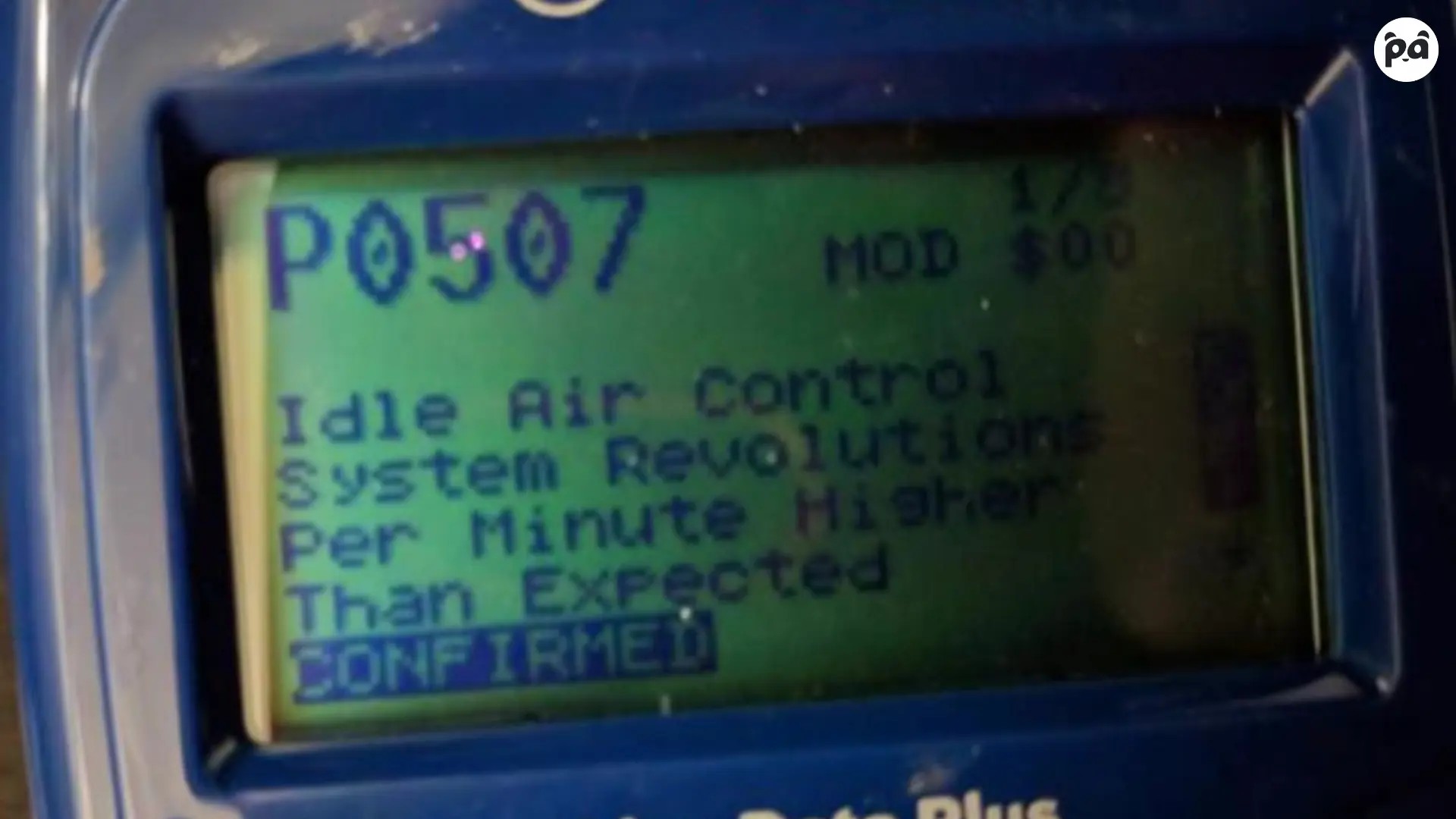

Decoding the P0507 Code: Idle Air Control System RPM Higher Than Expected

The P0507 diagnostic trouble code (DTC) is formally defined as Idle Air Control System RPM Higher Than Expected. This code is triggered when your car’s Powertrain Control Module (PCM) detects that the engine’s idle speed is higher than the manufacturer’s specified target RPM. When this discrepancy occurs, the PCM illuminates the Check Engine Light (CEL) on your dashboard, signaling a problem that requires your attention.

Understanding the idle control system is crucial to grasping the significance of the P0507 code. This system is responsible for maintaining a stable engine idle speed under various operating conditions, such as when the engine is cold, warm, or under load from accessories like the air conditioner. It achieves this by regulating the amount of air bypassing the throttle plate and entering the engine intake manifold.

Recognizing the Symptoms of a P0507 Code

When the P0507 code is present, your vehicle will often exhibit noticeable symptoms. These signs can help you identify a potential issue with the idle control system and prompt you to take action. Common symptoms associated with the P0507 code include:

- Engine Stalling or Dying at Stoplights: One of the most common and concerning symptoms is engine stalling, particularly when you come to a stop or when the engine is idling. This happens because the engine is not receiving the correct amount of air to maintain a stable idle.

- Rough Idling: You may experience rough or erratic idling, characterized by vibrations or shaking while the car is stationary. This indicates that the engine is struggling to maintain a smooth and consistent idle speed.

- Increased Fuel Consumption: A higher-than-normal idle RPM means the engine is working harder and consuming more fuel even when the vehicle is not moving. This can lead to a noticeable decrease in fuel economy.

- Check Engine Light is On: As mentioned earlier, the illumination of the Check Engine Light is a primary indicator of a P0507 code or other engine-related issues.

It’s important to remember that not all symptoms may be present simultaneously. Even a single symptom, especially the Check Engine Light in conjunction with rough idling or stalling, warrants a diagnostic check for the P0507 code.

Pinpointing the Root Causes of the P0507 Code

Several factors can contribute to the P0507 code. Understanding these potential causes is crucial for effective diagnosis and repair. The common culprits behind a P0507 code are:

- Vacuum Leaks: Unintended air leaks in the intake system are a frequent cause. Vacuum leaks allow unmetered air to enter the engine, bypassing the mass airflow sensor (MAF). This extra air disrupts the air-fuel mixture and can cause a high idle RPM. Common sources of vacuum leaks include cracked or disconnected vacuum hoses, intake manifold gasket leaks, and leaks around the throttle body or PCV valve.

- Dirty Throttle Body: Over time, carbon deposits and grime can accumulate in the throttle body, particularly around the throttle plate and idle air control passages. This buildup can restrict airflow and prevent the throttle plate from closing completely, leading to an elevated idle speed.

- Faulty Idle Air Control (IAC) Valve/System: The IAC valve is responsible for regulating airflow during idle. A malfunctioning IAC valve, whether due to electrical issues, mechanical failure, or carbon buildup, can fail to control idle speed properly, resulting in a P0507 code. In some modern vehicles, the IAC valve is integrated into the electronic throttle body.

- Dirty or Clogged Air Passages: Similar to a dirty throttle body, clogged air passages within the intake manifold or IAC system can restrict airflow and cause the system to malfunction.

- Mechanical Issues: In rare cases, mechanical problems such as a sticking throttle cable or a fault within the electronic throttle body itself can lead to a high idle condition and trigger the P0507 code.

Step-by-Step Guide to Diagnosing the P0507 Code

Diagnosing the P0507 code requires a systematic approach to pinpoint the underlying cause. Here’s a step-by-step diagnostic process you can follow:

- Scan for OBD-II Error Codes: Begin by using an OBD-II scanner to read all stored trouble codes in the vehicle’s computer. This will confirm the presence of the P0507 code and reveal any other related codes that might provide further clues.

- Visually Inspect the Throttle Body: Carefully inspect the throttle body for carbon buildup and obstructions. Check if the throttle plate moves freely and closes completely. Clean the throttle body using a throttle body cleaner and a soft cloth if necessary.

- Examine the Idle Air Control (IAC) Valve/System: If your vehicle has a separate IAC valve, inspect it for damage or carbon buildup. If possible, test the IAC valve’s functionality using a multimeter or scan tool. For vehicles with electronic throttle bodies, inspect the throttle body connector and wiring.

- Check for Vacuum Leaks: Thoroughly inspect all vacuum hoses, intake manifold gaskets, and connections for signs of leaks. You can use a vacuum gauge, smoke machine, or even listen for hissing sounds to help locate leaks. Spraying carburetor cleaner or soapy water around potential leak areas can also help identify vacuum leaks by observing changes in engine idle or bubble formation.

- Perform an Idle Relearn Procedure: After cleaning the throttle body or replacing any components, it’s often necessary to perform an idle relearn procedure. This allows the PCM to recalibrate the idle control system. The procedure varies depending on the vehicle make and model and may involve using a scan tool or specific driving cycles.

- Inspect Wiring and Connectors: Check the wiring and connectors associated with the IAC valve, throttle body, and MAF sensor for any signs of damage, corrosion, or loose connections.

- Evaluate Battery and Charging System: Although less common, a weak or unstable battery can sometimes contribute to idle control issues. Test the battery voltage and charging system to rule out any electrical problems.

Effective Solutions for Resolving the P0507 Code

Once you’ve identified the cause of the P0507 code, you can implement appropriate solutions. The fixes can range from simple DIY tasks to more complex repairs requiring professional assistance. Here are common solutions for addressing the P0507 code:

- Perform an Idle Relearn Procedure: In some cases, especially after cleaning the throttle body, simply performing an idle relearn procedure may resolve the P0507 code. Consult your vehicle’s repair manual or online resources for the specific procedure for your car model.

- Clean the Throttle Body: If carbon buildup is found in the throttle body, thoroughly cleaning it with a throttle body cleaner can often restore proper idle control. Ensure you follow the instructions on the cleaner and use appropriate safety precautions.

- Replace the IAC Valve or Components: If the IAC valve is faulty or beyond cleaning, replacement is necessary. Ensure you use a high-quality replacement part that is compatible with your vehicle. For electronic throttle bodies, component replacement might involve replacing the entire throttle body assembly.

- Repair Vacuum Leaks: Locate and repair any vacuum leaks by replacing cracked hoses, tightening connections, or replacing faulty gaskets.

- Professional OBD-II Scanner Reset: After completing repairs, use an OBD-II scanner to clear the P0507 code and any other related codes. In some cases, a professional-grade scanner may be required for proper system reset.

The Importance of Auto Detailing for Engine Health

While addressing mechanical issues like the P0507 code is crucial, regular car detailing, particularly engine bay detailing, plays a significant role in preventing such problems and maintaining overall engine health.

Keeping your engine compartment clean helps prevent the accumulation of dirt, debris, and grime that can contribute to issues like a dirty throttle body or clogged air passages. Regular engine detailing ensures that critical components like the throttle body, IAC valve, and air intake system remain free from obstructions and can function optimally.

Furthermore, a clean engine bay makes it easier to spot potential problems like leaks or damaged hoses during routine maintenance checks. Engine bay detailing is not just about aesthetics; it’s a proactive step in preventing costly repairs and ensuring long-term engine performance.

Understanding the Costs Associated with P0507 Repairs

The cost of repairing a P0507 code can vary depending on the underlying cause and the required repairs. Here’s a breakdown of potential cost factors:

- Parts Pricing: The cost of parts can range from relatively inexpensive items like vacuum hoses or throttle body cleaner to more costly components like an IAC valve or electronic throttle body. An air filter, which might be related to preventative maintenance, can cost around $20, while an IAC valve can range from $100 to $200 or more.

- Labor Estimates: Labor costs will depend on the complexity of the repair and the hourly labor rate of your chosen mechanic or dealership. Labor rates can vary significantly by location and shop. For P0507 repairs, labor could range from 1 to 3 hours, depending on the diagnosis and repair procedures.

- Total Repair Cost: The total cost to address a P0507 code can range from around $100 for simple fixes like throttle body cleaning or vacuum hose replacement to $500 or more for more complex issues requiring IAC valve or throttle body replacement and more extensive labor.

Preventative Measures to Avoid Future P0507 Issues

Preventing the recurrence of a P0507 code involves proactive vehicle maintenance and good driving habits. Here are effective preventative strategies:

- Regular Vehicle Maintenance: Adhering to your vehicle manufacturer’s recommended maintenance schedule is crucial. Regular servicing, including air filter replacement, throttle body cleaning (if recommended), and vacuum hose inspections, can prevent many issues, including those leading to a P0507 code.

- Use Quality Fuel: Using high-quality fuel from reputable sources can contribute to cleaner engine operation. Some premium fuels contain additives that help keep fuel injectors and intake systems clean, potentially reducing carbon buildup.

- Smooth Driving Habits: Avoid aggressive driving habits like rapid acceleration and hard braking, which can put unnecessary stress on the engine and its components. Smooth and moderate driving can contribute to overall engine longevity and reduce wear and tear on the idle control system.

- Regular Air Filter Replacement: A clean air filter is essential for proper engine airflow. Replacing the air filter at recommended intervals prevents dirt and debris from entering the intake system and potentially clogging air passages or contaminating the throttle body.

Seeking Professional Diagnostics and Repair

While some P0507 code issues can be resolved with DIY efforts, there are situations where professional expertise is invaluable. If you are not comfortable performing diagnostic procedures or repairs yourself, or if the problem persists after your initial attempts, seeking professional help is recommended.

Certified mechanics have the training, experience, and specialized tools, including advanced scan tools and smoke machines, to accurately diagnose and repair complex issues related to the P0507 code. When in doubt, consulting a professional ensures that the problem is correctly identified and resolved, preventing potential further damage or complications.

Common Pitfalls to Avoid During P0507 Diagnosis and Repair

When addressing a P0507 code, it’s important to avoid common mistakes that can lead to misdiagnosis or ineffective repairs. Key pitfalls to watch out for include:

- Assuming a Quick Fix: The P0507 code can be caused by various underlying issues, and a hasty diagnosis can lead to overlooking the actual root cause. Avoid assuming it’s a simple fix and conduct a thorough diagnostic process.

- Ignoring Related Issues: The idle control system interacts with other engine systems. Ignoring related problems like vacuum leaks or sensor malfunctions can prevent a successful P0507 repair.

- Skipping the Relearn Procedure: Forgetting to perform an idle relearn procedure after cleaning or replacing components can result in the code returning or the idle issue persisting.

- Failing to Recheck for Codes: After completing repairs, always re-scan for trouble codes to ensure that the P0507 code is cleared and no new codes have appeared.

Real-World Case Studies of P0507 Code Scenarios

The P0507 code can manifest in various ways depending on the specific underlying issue. Here are a few case studies illustrating diverse scenarios and solutions:

- Case 1: The Gunked-Up Throttle Body: A vehicle exhibited a P0507 code along with rough idling. Diagnostic inspection revealed a heavily carbonized throttle body. Cleaning the throttle body and performing an idle relearn procedure completely resolved the issue. The repair cost was minimal, primarily for labor and throttle body cleaner.

- Case 2: The Elusive Vacuum Leak: A car presented with a P0507 code and high idle. Initial visual inspection didn’t reveal any obvious vacuum leaks. However, smoke testing identified a small crack in an intake manifold hose. Replacing the hose and clearing the code resolved the problem. The cost was moderate due to the labor involved in smoke testing and leak detection.

- Case 3: Damaged IAC Valve Wiring: A vehicle experienced intermittent P0507 codes and erratic idling. Diagnostic testing revealed a damaged wire in the IAC valve wiring harness due to rodent damage. Repairing the wiring and ensuring proper connections resolved the issue. The repair cost was moderate, mainly for diagnostic labor and wiring repair.

Conclusion: Successfully Resolving P0507 Code Challenges

Successfully navigating the challenges posed by a P0507 code involves a combination of understanding the code’s meaning, recognizing its symptoms, conducting thorough diagnostics, and implementing appropriate solutions. Whether you choose a DIY approach or seek professional assistance, remember that accurate diagnosis and quality repairs are key to resolving the issue effectively and ensuring your vehicle’s long-term health. By staying proactive with regular vehicle maintenance and addressing issues promptly, you can minimize the chances of encountering P0507 codes and maintain optimal engine performance.

Frequently Asked Questions About the P0507 Code

Q: Can a P0507 code lead to long-term engine damage if ignored?

A: Yes, if the underlying cause of the high idle is not addressed, it can lead to increased engine wear, potential overheating, and other engine-related problems over time.

Q: Will a P0507 code cause my car to fail an emissions test?

A: Yes, the presence of a P0507 code and the illuminated Check Engine Light will likely result in a failed emissions test in most regions.

Q: Is it safe to drive my car with a P0507 code?

A: While you might be able to drive with a P0507 code, it is not recommended. The high idle condition can lead to reduced fuel economy, engine stalling, and potentially unsafe driving situations. It’s best to diagnose and repair the issue as soon as possible.