For automotive enthusiasts diving into DIY modifications, achieving a perfect fit for custom parts is paramount. This is where 3D scanning technology steps in, offering a powerful tool to capture the intricate contours of your vehicle. However, a common misconception exists regarding the direct usability of these 3D scans, especially when it comes to modifying your car body.

As demonstrated by [Ding Dong Drift] in his project car 3D scan, the raw scan data isn’t immediately ready for direct manipulation as a design model. His objective, much like many car modders, was to create custom attachments. While scanning the car body seems like a direct route, understanding the nature of 3D scans is crucial. The key takeaway from experts? Avoid the temptation to directly edit or use the 3D scan as your primary model. Instead, leverage it as a precise reference.

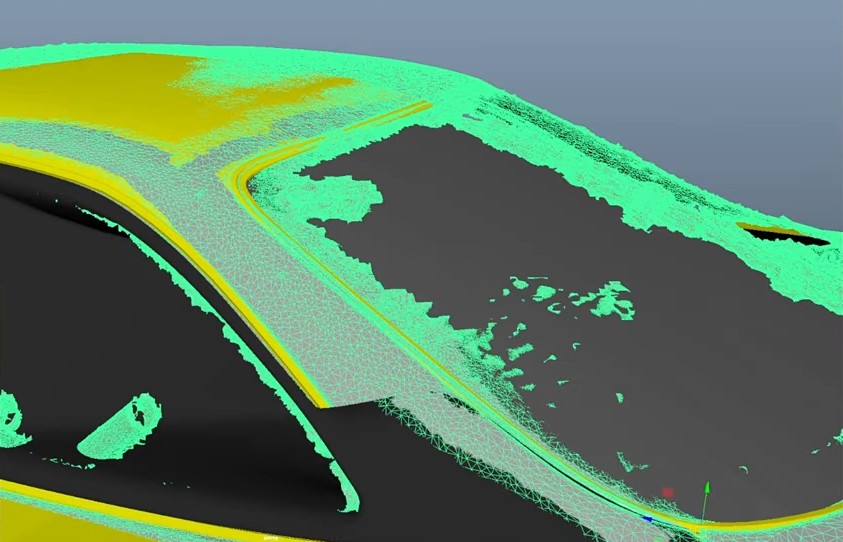

When you scan a car body, the output is essentially a point cloud – a massive collection of data points in 3D space. This point cloud is then processed to create a mesh, resulting in a 3D model with an exceptionally high polygon count. While dimensionally accurate in representing the scanned surface, this model is inherently fragmented. Scanners can only capture what’s visible, leading to gaps and imperfections in complex car body shapes. Furthermore, the sheer complexity of these high-polygon models makes them cumbersome and inefficient to work with directly in CAD (Computer-Aided Design) software for designing parts.

In practical application, exemplified by [Ding Dong Drift]’s workflow, the optimal approach involves utilizing the 3D car body scan as a dimensional reference for CAD modeling. In his case, possessing a pre-existing 3D model of his car, he employed the scan of his car’s rear end to meticulously refine this model. This refinement process ensures the digital model precisely mirrors the contours of his actual vehicle at critical points. By doing so, he gains confidence that any custom parts designed using the refined CAD model will achieve a flawless fit on his car body.

The true power of 3D scanning emerges when dealing with components that demand tight integration with existing car structures, particularly where flat surfaces and right angles are absent. We’ve previously highlighted the effectiveness of photogrammetry in scanning a van interior for an off-grid camper conversion. The advancements in 3D scanning technology have only amplified these benefits. Modern handheld scanners capable of generating dimensionally accurate scans have become increasingly accessible and user-friendly. These tools empower automotive enthusiasts and professionals alike to efficiently capture car body geometries for a wide range of applications, from custom part design to complex automotive repairs and modifications, always with the scan serving as the bedrock of accuracy for subsequent CAD work.